INSTRUCTIONS

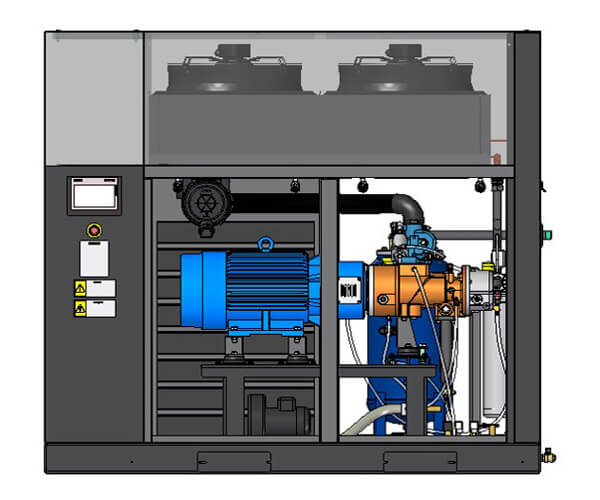

The injected water of the SWV-series functions as both a sealant and a coolant. It reduces leakage between the rotors and the housing, which can improve a compressor’s efficiency by 15% when compared to a dry screw compressor. Injected water also mixes with the compressed air to efficiently cool down and dissipate the heat generated in the compression process, thus allowing an almost isothermal compression.

The SWV series airends were designed to provide good air quality, perfect performance, and high reliability. It generates 100% oil-free compressed air for all applications where clean air is crucial in producing products of the highest quality.

Features

Isothermal compression: Optimum efficiency is achieved in isothermal

compression. For theoretically adiabatic compression, inlet air at 20°C

can be compressed at 7 bar(g) with a temperature of over 250°C. This heat

generated from the compression process is removed by injecting water into

the compression chamber. By using injected water as coolant, the

temperature of the compression chamber can be cooled down to 40°C,

creating a highly efficient and isothermal process. The water film also

seals the gaps between the rotors and the housing to reduce internal

leakage.

Reliable sealing system: the airends of the SWV series are supported by

precise roller bearings with oil lubrication. The compression chamber and

bearing chamber is separated by a buffer chamber with an oil seal and a

water seal. The leakage from the oil side into the compression chamber is

avoided.

applications

Online

Chat

Online

Chat