INSTRUCTIONS

The Fusheng SA series compressors are built with advanced patented helical teeth rotors and delicately processed one-piece casings. These rotary screw air compressors use premium technology to run efficiently and at low cost. They run on 5.5 kW to 220 kW of horsepower, have discharge volumes between 0.85m3/min and 42.0m3/min (operating pressure 7.0kg/cm2G), and meet the international energy efficiency standards. The well-balanced, low vibration, quiet, and overall ergonomic designs enable easy maintenance and space planning, featuring the advanced and thoughtful design of the high-efficiency flow field in the cooling channel and high-precision oil filter. The screw air compressor comes with an intelligent human-machine interface control system and a computerized self-diagnostic safety feature. It is an industrial grade compressor designed for wide industrial applications.

The Fusheng SA series is verified by TUV Rheinland, a third-party testing laboratory. The design of the compressed air system is based on the five elements (the 5 S’s) that we want our products to provide for the customers - security protection (Safety), ease of Service (Service), stability and reliability (Stable), the international certification (Specification - compliant) and Energy Saving (Cost Saving).

Features

All parts are specifically selected, and the environmental temperature

tolerance is increased to 40 ℃. All oil pipes are designed to have a high

temperature tolerance. The structure is designed for continuous use, where

consumable parts are drastically reduced, and the unit is easy to maintain.

The efficiency of the low-speed drive was also enhanced to promise a high

energy-efficiency ratio and minimal vibration and noise.

High Performance Airends --- The rotors are manufactured with special

techniques developed from Fusheng’s R&D center in Germany and are 100%

reliable for continuous operation. The upgraded high-end gear tooth allows

for high capacity usage and energy-saving demands. The optimized air

suction design maximizes rotor usage to improve compression efficiency.

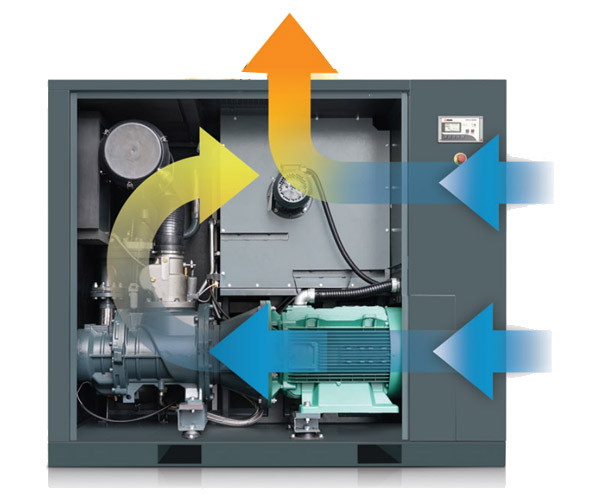

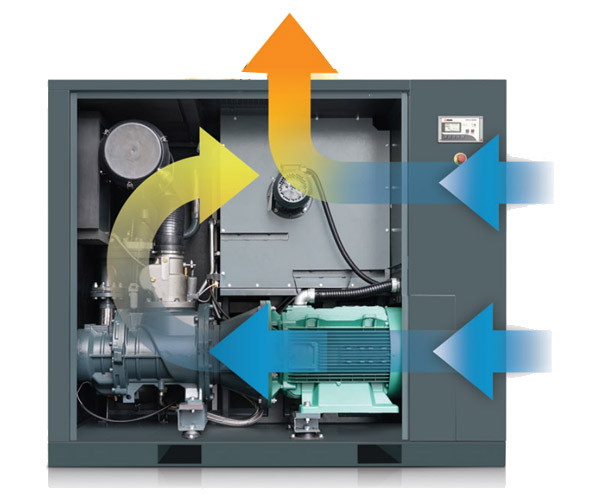

e-COOL™ is environmentally-friendly technology that combines a smart

compressor layout, strategic component selection and location, and cooling

airflow and operation to minimize the impact of temperature on a

compressor’s efficiency and reliability. A combination of high efficiency

front-tilted centrifugal fans and independent cooling channels are adopted

in the design to guarantee strong forced convection and cooling effects.

The decreased thermal stress extends the life of components and lowers

internal compressor temperatures, resulting in better volumetric and

electrical efficiency.

applications

-m.jpg)

Online

Chat

Online

Chat