After years of practice and working with clients, the BSR series screw refrigerant compressors have acquired numerous awards and certifications from various domestic and international institutes, including the UL(USA), CE mark (EU), PED(EU), ISO 9001, the Symbol of Excellence award (Taiwan), and many more. Each compressor is under 42bar hydraulic pressure examination to ensure the safety of its structure.

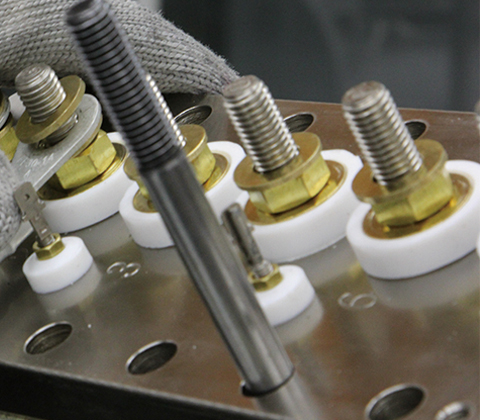

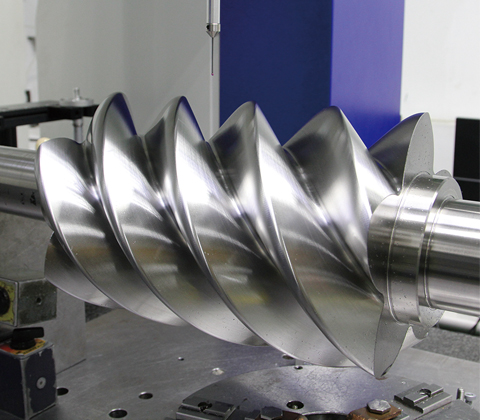

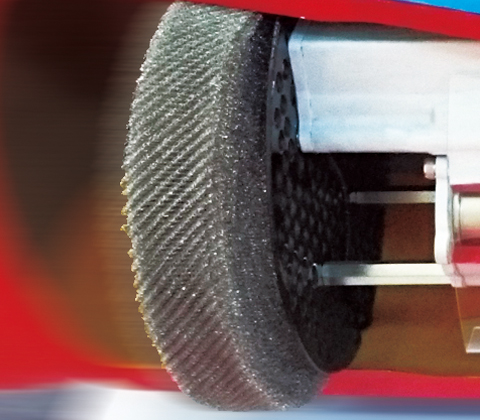

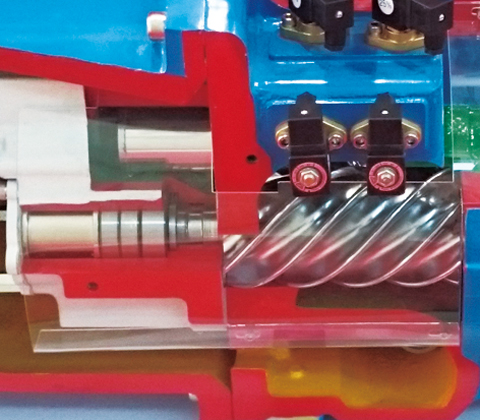

The BSR screw refrigerant compressors are built with high-precision helical rotors and they feature minimal backlash, highly efficient operation, and compact structures. The compressors are small, easy to install, and they minimize low pressure loss and vibration. These units offer precise volume control, and a long service lifespan. The BSR213S to BSR616 produce discharge volumes of 143 to 2351m3/hr (60Hz).

The BSR series have been the best selection for various application industries, including air conditioning systems, hi-tech dust-free rooms, climate control rooms, and food refrigeration systems.

Online

Chat

Online

Chat